MISCELLANEOUS PROJECTS

CARBON FIBRE INFUSION

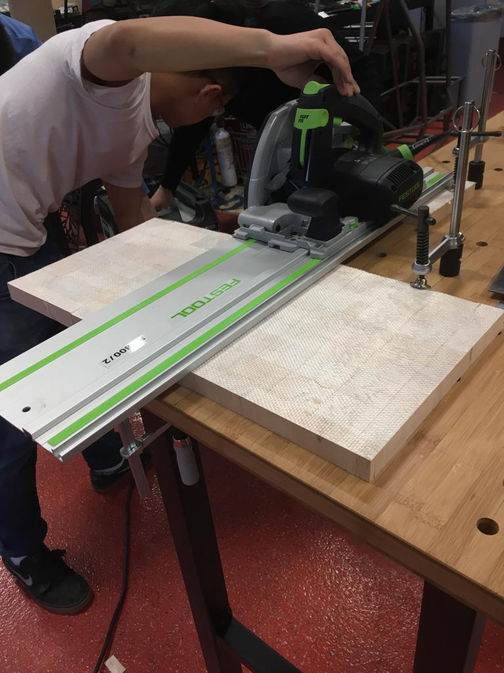

Carbon Fibre Infusion Process was used to make the panels for our chassis. The goal for the 2017-2018 Solar Car was to use a carbon fibre based chassis. The infusion process consisted of combining different materials to be insulated in a vaccum environment where resin is used to seal these materials together making a strong panel. Mechanical testing of the panels were done post infusion

Materials use:

- Balsa Wood

- Carbon Fibre

- Aluminum Inserts

- Vaccum Bag

- Resin

- Plastic Piping

Material Choices:

- Balsa Wood --> Very light wood that are used for support between the aluminum inserts

- Carbon Fibre --> Very strong material in one direction

- Aluminum Inserts --> Light

Below are photos from the construction period of the infusion:

Below are two videos of the infusion process:

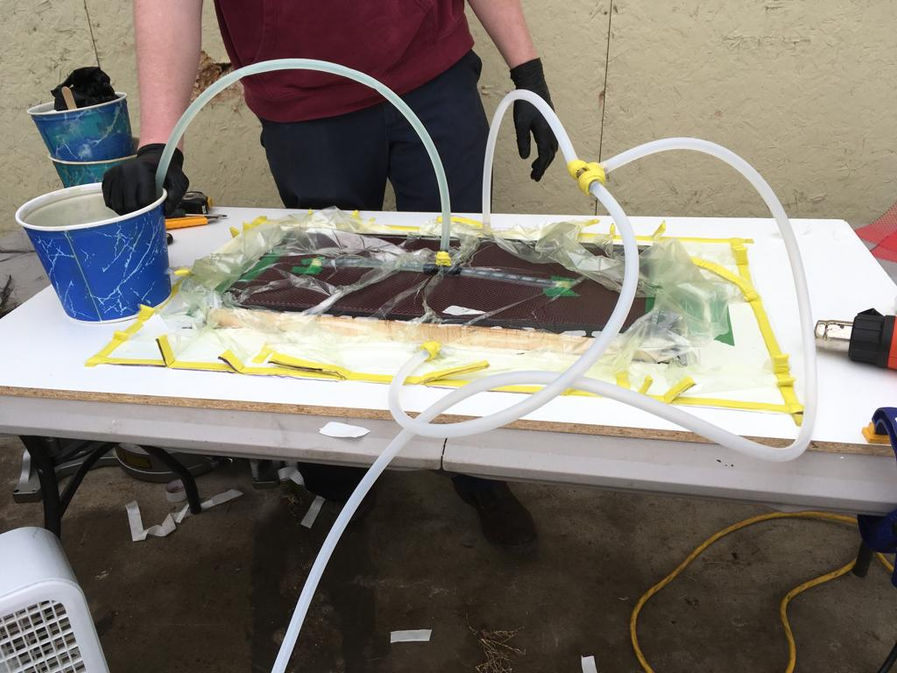

SOLAR CELL ENCAPSULATION PROJECT

The image below shows a layout of the initial frame for the encapsulation project. Where the plan is to lay the solar cells out into the middle frame, then take another set of panel and lay it on top allowing a vacuum shell to be trapped between the cells and wood pieces. The hose to help vacuum out the air will be between the top and bottom panels through the holes. We hope that the wood pieces will give the encapsulation a frame. The encapsulation process will increase the mechanical ability of the solar cells. Solar cells are brittle as it is necessary to apply a frame of protection allowing it to be bent and not break.

Material Used:

- Wood for frame

- Vacuum Bag

- EVA (Polymer material used to encapsulate the cells)

Encapsulation Process:

2. The solar cells will be soldered in series

3. EVA layers on top and bottom of solar cells

4. Apply the Vacuum and compressor

5. Using a heat gun to seal

6. Laminate the solar cells

7. Mechanical Rig will be used to test the efficiency of the solar cells

This project is still in progress.